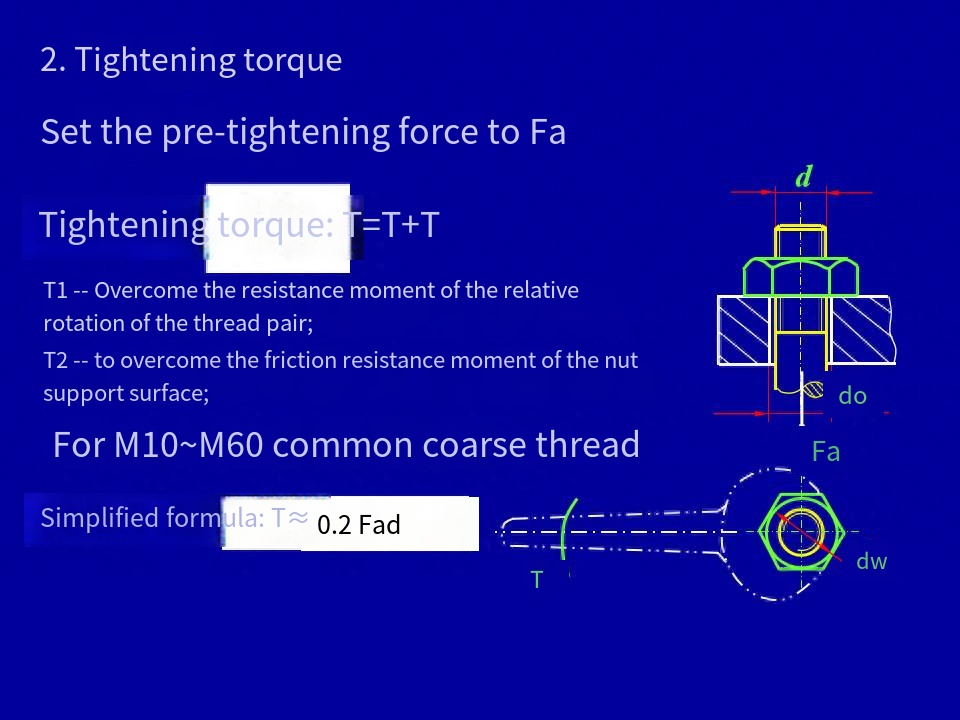

1. Ipni ulashni oldindan mahkamlashIsh yukining ta'siridan oldin vintni oldindan mahkamlash kuchi ta'siriga duchor bo'ladi.

1. Oldindan mahkamlashning maqsadi

1) Ulanishning qattiqligini oshiring

2) Qattiqlikni oshiring

3) Bo'shashmaslik qobiliyatini yaxshilang

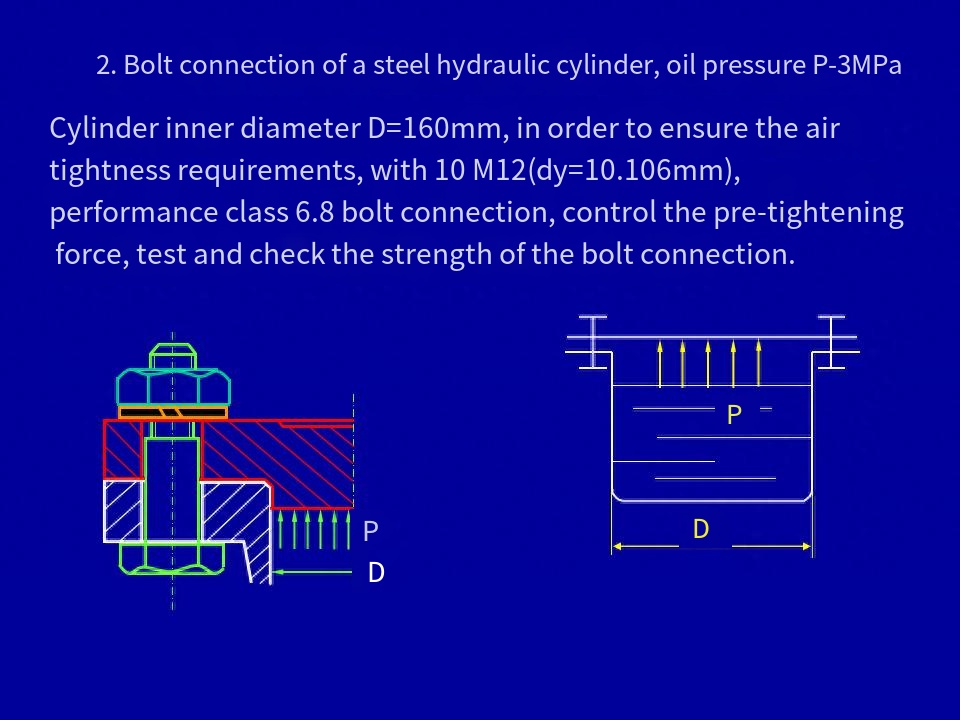

Oldindan qoldiq yukni aniqlash:1) Ish yukida o'zgarish yo'q:FR FR= (0,2~0,6)2) Ishchi yuklama o'zgaradi:FR= (0,6~1) F3) Sızdırmazlık talablari mavjud:Fp FR=(1,5~1,8)

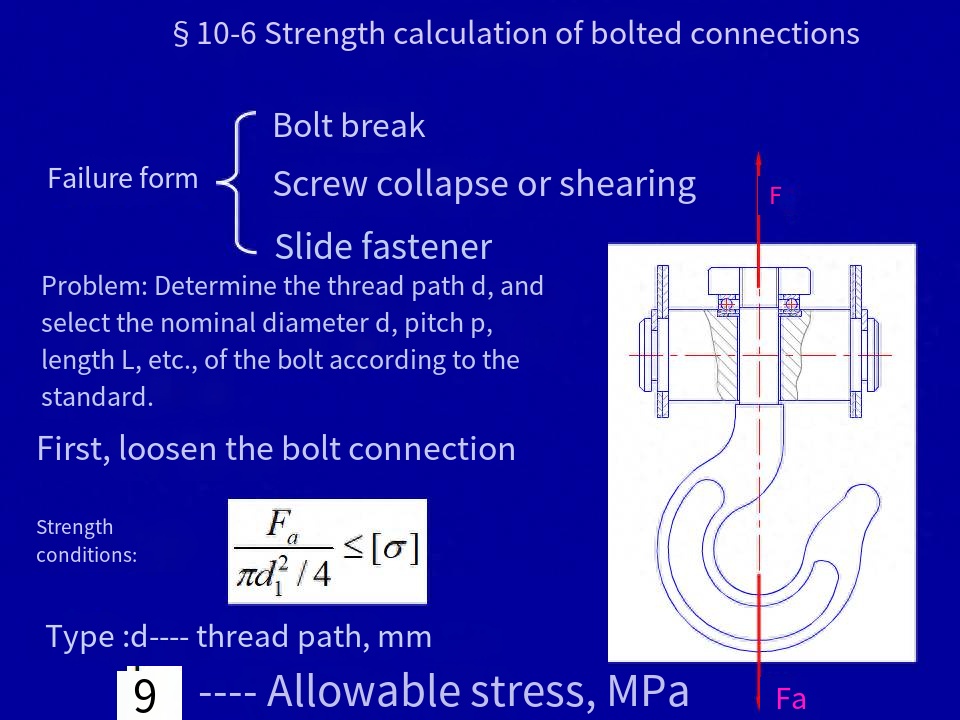

10-7 dollar Materiallar va murvatlarning ruxsat etilgan kuchlanishlari1.Boltlar mexanik xususiyatlariga ko'ra tasniflanadi va milliy standartda quyidagilar nazarda tutilgan: Boltlar 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, 9.8, 10.9, 12.9 4, 5, 6, 8, 9, 12 murvatlari

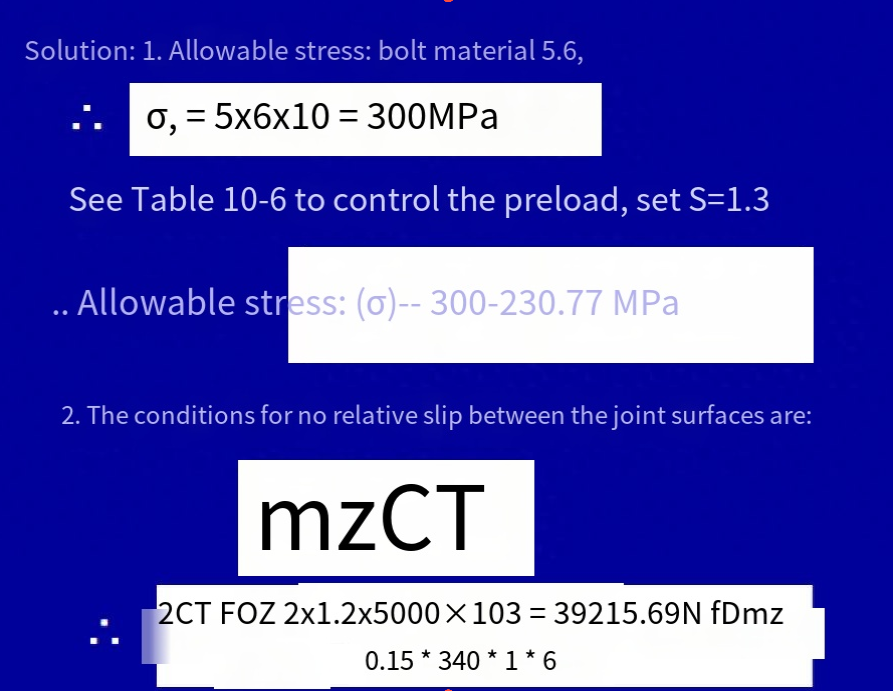

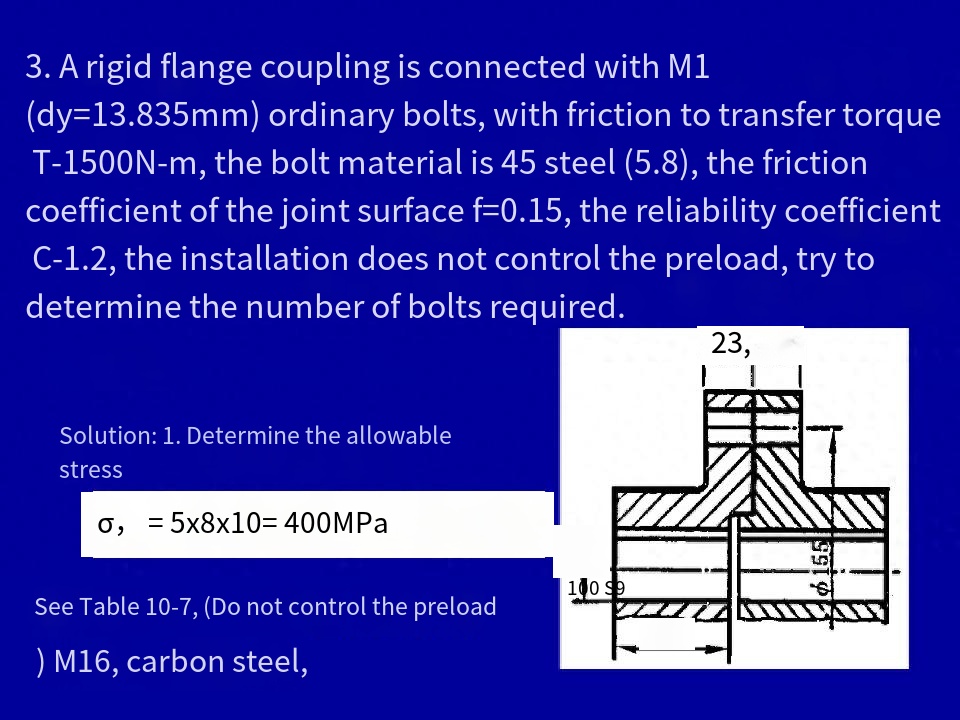

2. Boltning ishlash darajasi kodining ma'nosi: Birinchi raqam: murvat materialining kuchlanish chegarasini bildiradi.Shundan 1/100.s= birinchi raqam x 100Ikkinchi raqam: murvat materialining chiqish chegarasini bildiradi.O'n barobar kuch chegarasi s.Sigma.= Birinchi raqam x ikkinchi raqam x 10Masalan: 4.6 sinf boltsr=4×100-400MPa, s, =4×6×10-240MPa3.Tishli ulanishning ruxsat etilgan kuchlanishi Darslikning 10-6 va 10-7-jadvallariga qarang

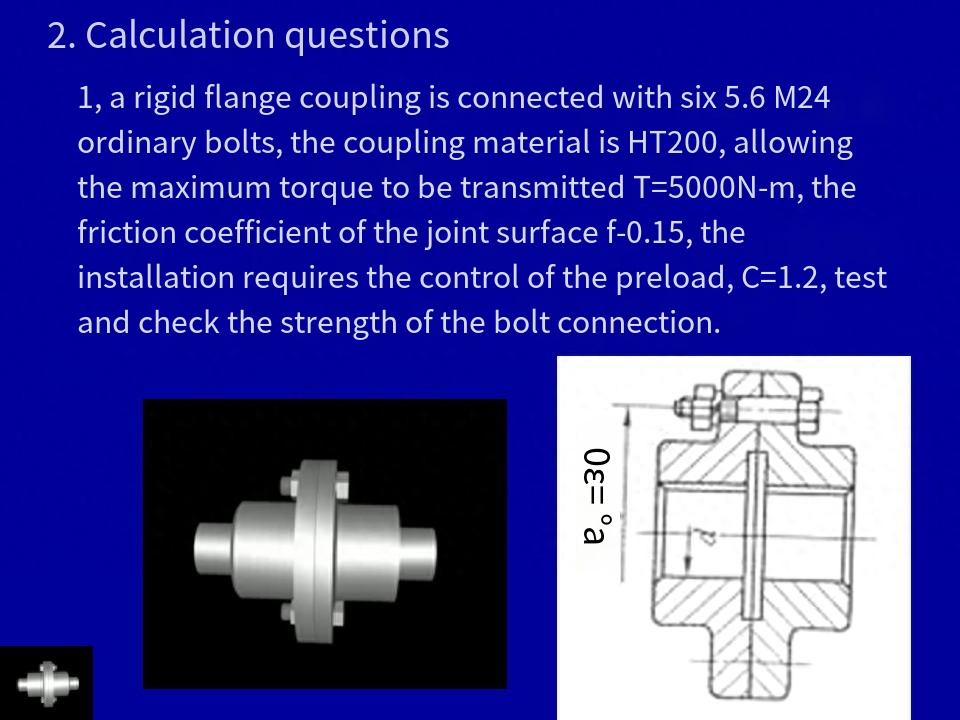

2. Hisoblash uchun savollar

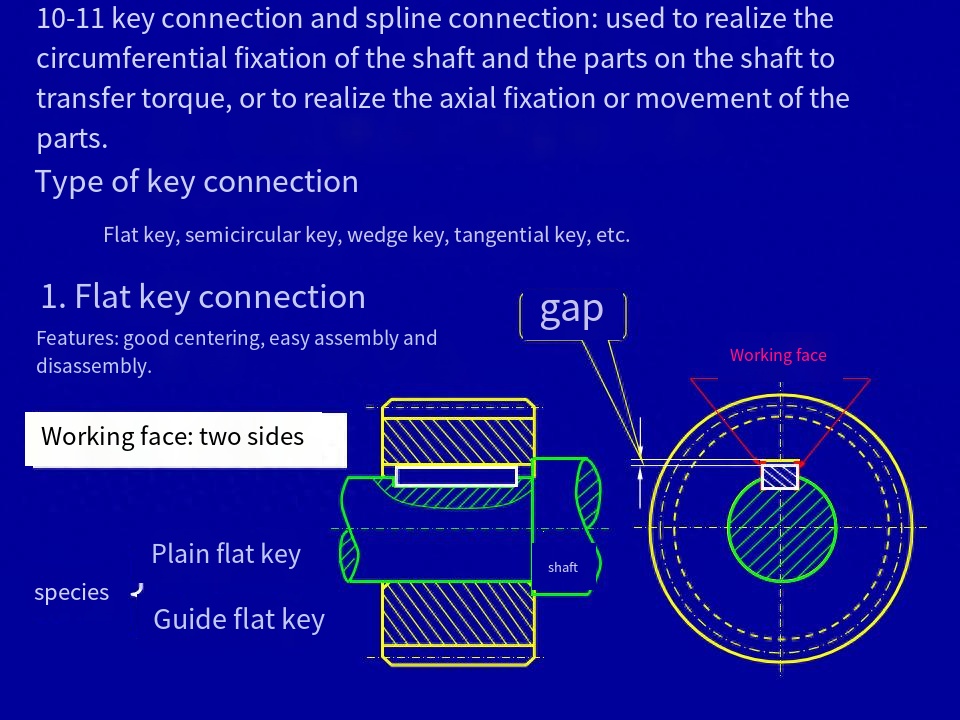

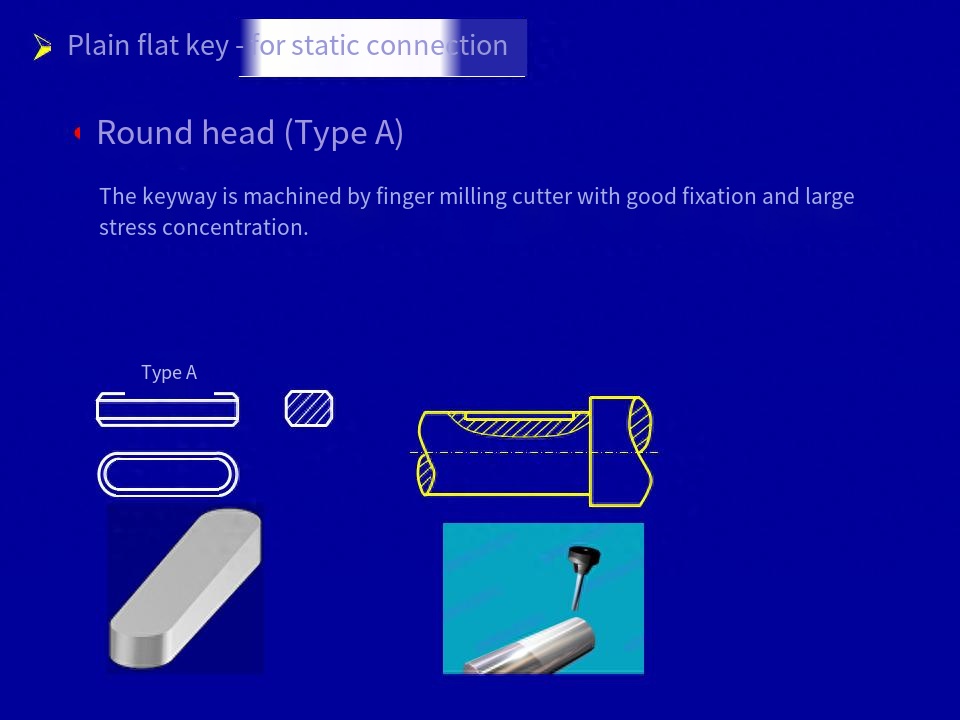

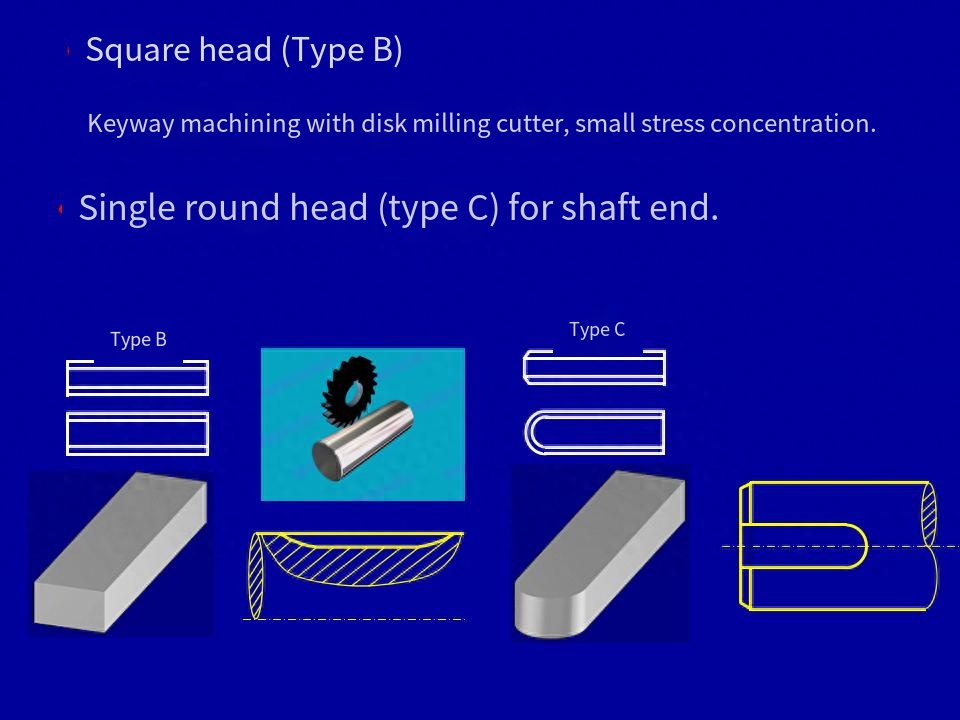

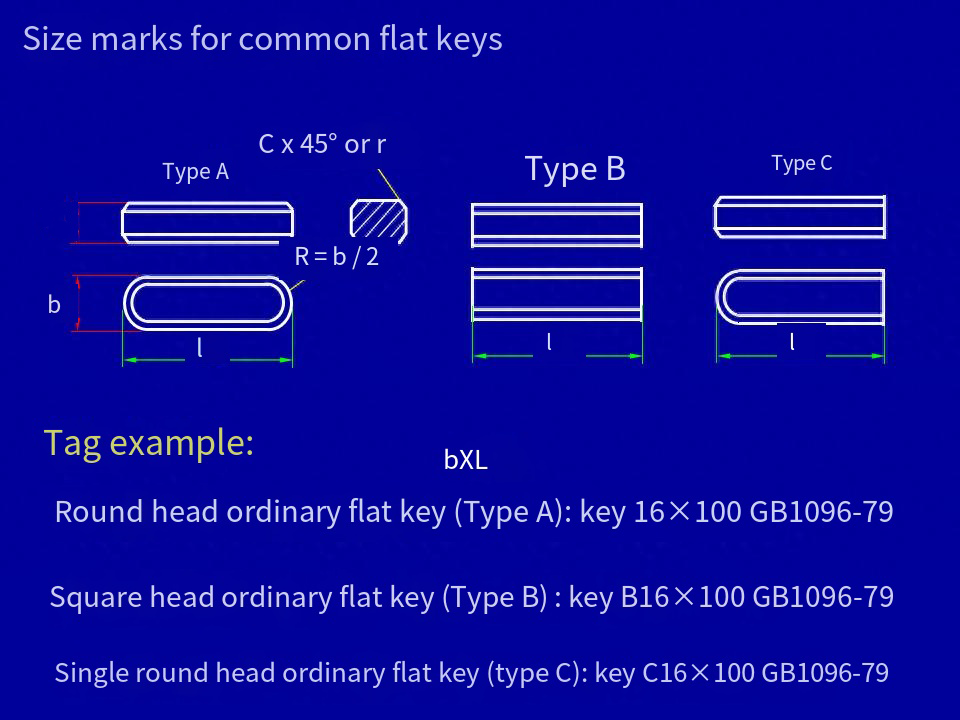

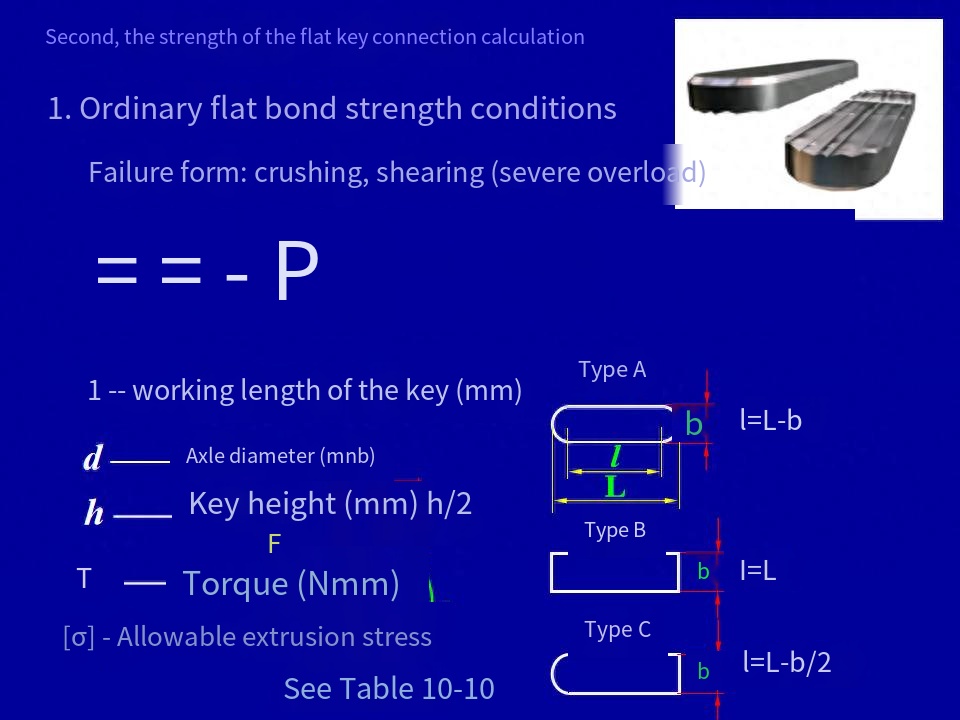

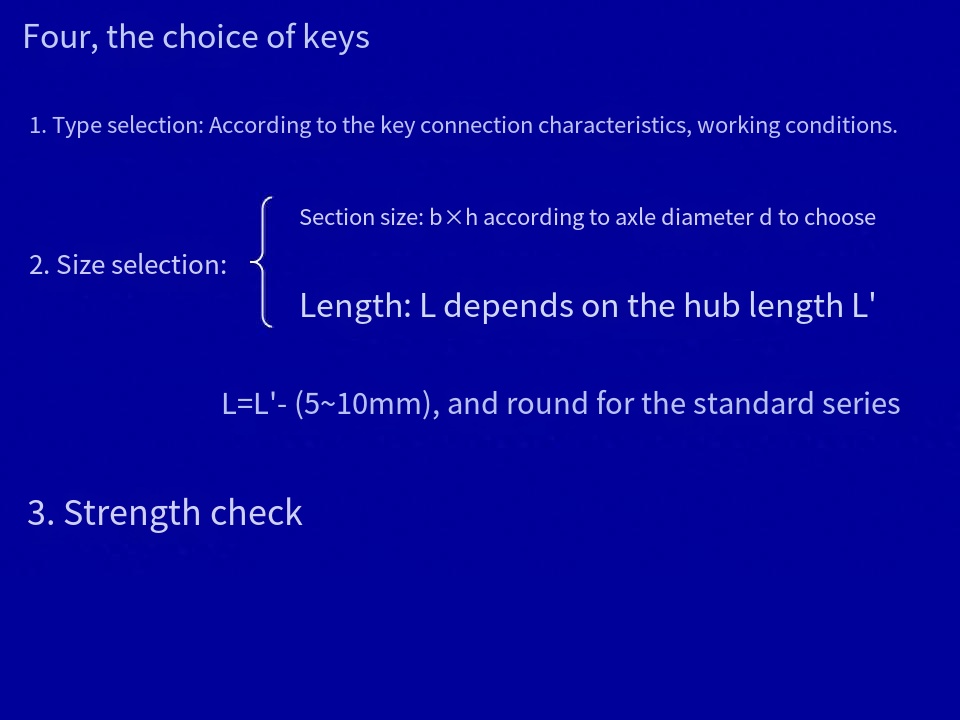

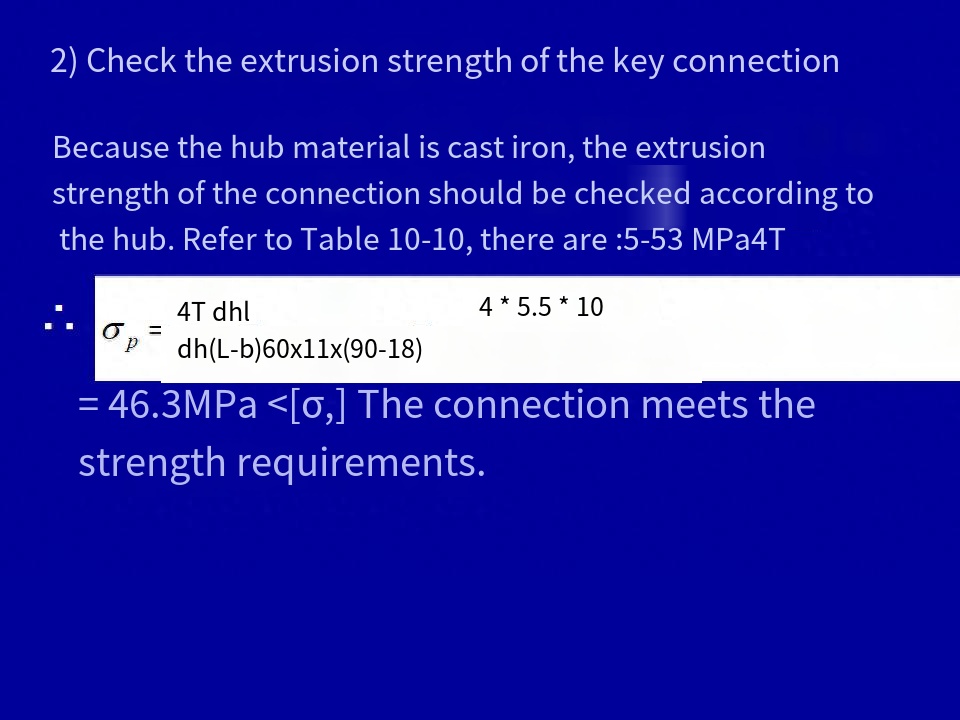

Kalit va po'lat mil aloqasi orqali quyma temir tekis tishli silindrsimon tishli, tishli mildagi milning kesimi diametri d=60mm, uya uzunligi L'=100mm, uzatiladigan moment T=5,5×105N.mm, kichik zarba ishlang, ushbu kalit aloqasini loyihalashtirishga harakat qiling.Yechim: 1) Kalitning materialini, turini va hajmini aniqlang, chunki uya cho'yandan yasalgan, kalitning materiali 45 po'latdan tanlanishi mumkin va o'rtasida eksenel harakat yo'q. tishli va mil, shuning uchun A tipidagi oddiy yassi kalit tanlanadi.O'qning diametri d=60mm, markaz uzunligi 100mm bo'yicha, 10-9-jadvalga qarang, Qabul qiling:b=18mm, h=11mm, L=90mm.

Yuborilgan vaqt: 2023 yil 13-sentabr